technology

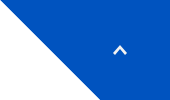

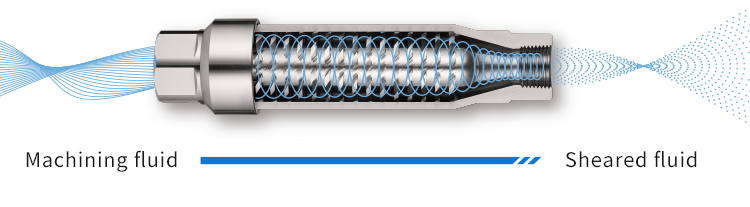

Machining fluid shearing technology

Just installing SIO in a machine tool (grinding machine, machining center) will greatly improve the performance of machining fluid, demonstrate orders of magnitude of cooling effect, and incomparable cleaning effect.

This will revamp QCD (quality, cost, delivery time), which is an important task at the processing site. It also contributes to the processing of difficult-to-cut materials.

SIO technology

-

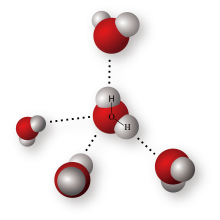

SIO breaks the hydrogen bond of water and reduces the molecular aggregate.

The surface tension and viscosity of water are lowered, the degree of penetration into a narrow part is raised, the water becomes smooth and lubricity also increases. This enhances the cooling effect, improving processing efficiency and processing quality.

-

The superior stirring ability of SIO improves the wettability of machining fluid.

The superior stirring ability of SIO improves the wettability of machining fluid and can use machining fluid without waste and improves the cooling function, cleaning function and lubrication function.

-

A special internal structure generates micro-fine bubbles.

Shock wave caused by explosion of micro-fine bubble removes sludge and chips adhering to grinding stone, drill, workpiece, and it improves processing efficiency and improves processing quality.

Japanese Patent No.6245397, No.6245401, No.6393389, No.6393441 and No.6673591

United States Patent No.10279324 and No.10668438

Germany Patent No.102017116506

European Patent No. 3357641

Chinese Patent No.108284350

Korea Patent No.10-1835986 and No.10-1838429

Taiwanese Patent No.I624329 and No.I627022

*Other foreign patents are now pending

SIO cross section

Benefits of SIO

[Problem]

Grinding is a neck process and processing speed needs to be increased

[Effect]

Increase the amount of cut, enabling machining with increased feed rate, improve efficiency, eliminate bottleneck

[Problem]

Improve the roughness of the finished surface, realize mirror finish

[Effect]

Since the sharpness of the grinding stone improves, it is possible to decrease the grain size and to increase the depth of cut and process it. As a result, the surface roughness is as fine as the particle size

[Problem]

The life of the grinding wheel, the dress cycle is short and the operation efficiency of the machine is bad

[Effect]

Improve the clogging of grinding wheel, extension of grinding wheel life and dressing cycle, improve machine operation rate

[Problem]

Struggling with difficult-to-cut materials (ceramic, stainless steel, carbon, chrome plating etc.) (time, yield, completeness)

[Effect]

Increase speed, grinding wheel life, dress cycle, improve grinding rate drastically than conventional machining

SIO Case Study 1: Carbide grinding performance

Precision CNC forming grinding machine Amada Machine Tool (MEISTER G3)

Technical Data

Grinding wheel: SDC200 Φ200x10Tx31.75 /

Material: Carbide, length 50x width 20

| Current | With SIO | ||

| Rough grinding amount mm | 0.300 | 0.300 | |

| Fine grinding amount mm | 0.030 | 0.030 | |

| Rough cut / time mm | 0.005 | 0.030 | 6times more than current |

| Precision cut / time mm | 0.002 | 0.010 | 5times more than current |

| Spark out | 3times | 3times | |

| Processing time | 18min | 4min | about 78% reduction in time |

Benefits

- Machining time shortened (greatly improved efficiency), because cutting can be greatly increased

- Damage to the grinding wheel is reduced and abrasion loss is reduced (cost reduction)

- Since the workpiece has no heat, warpage is reduced (grinding rate: 99.6%)

SIO Case Study 2: silicon nitride grinding performance

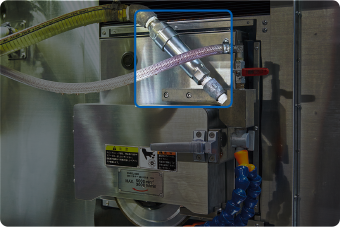

Precision molding grinder Kuroda Seiko GS-30FL II

Technical Data

Grinding wheel: SD400 /

Material: Si3N4 50×50×4

| Current | With SIO | ||

| Total grinding amount mm | 0.17 | 0.17 | |

| Fine grinding amount mm | 0.02 | 0.02 | |

| Rough cut / time mm | 0.002 | 0.005 | |

| Spindle rotation rpm | 1480 | 2300 | |

| Grinding amount mm | 0.154 | 0.17 | |

| Wheel abrasion mm | 0.016 | 0 | Wheel abrasion is 0 |

| Processing time | 1h14m | 17m2s | about 77% reduction in time |

Benefits

- Increase depth of cut and shorten processing time (greatly improved efficiency)

- Abrasion loss suppressing, reduce grinding wheel damage (cost reduction)

- High precision machining is possible even with difficult-to-cut materials (grinding ratio: 99.6%)